Design for manufacturability

Much like trying to work on a modern vehicle, where everything is engineered to fit into a space not for maintainability, the designs we receive or create are not always optimal. They look great and serve the purpose of the end goal. However, in most cases, they take longer to manufacture than they should.

We can reduce the time it takes to produce the product if we apply some lean thought or designing for manufacturability.

Design for Manufacturability (also sometimes known as design for manufacturing or DFM) is the general engineering practice of designing products in such a way that they are easy to manufacture. The concept exists in almost all engineering disciplines, but the implementation differs widely depending on the manufacturing technology. DFM describes the process of designing or engineering a product in order to facilitate the manufacturing process in order to reduce its manufacturing costs. – Wikipedia

Here are 5 ways to design for manufacturability.

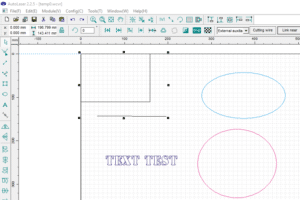

- Check your designs for unneeded geometry – Those vector curves look great, however have you checked the number of nodes? Check to see if you can reduce the number of nodes/vectors to simplify the design. Each node/vector increases the time to process the design. Straight lines are quicker than curves.

- Check your design processing type – Cutting a vector is faster than engraving, can you optimize the design to use more cutting (lower power, higher speed) instead of engraving details.

- Check your design process order – Most software for processing (CNC) allows you to check and re-order the way a design is processed. You can reduce the processing time if you can order the elements being processed to reduce the travel of the machine. Process elements with the shortest path in mind.

- Check the estimated work time – Can you reduce the work time for the overall job by processing multiples at one time? If the job is not a one-off, can you stack the jobs to process them and reduce the setup time between each run?

- Material placement – Can you reliably place the material quickly between runs? If you must spend time tweaking the material placement each time the job needs to run, you are wasting time. Create a fixture that will allow you to place the material in the same place each time to reduce the setup time for each run.

Bonus Tips

Minimizing the number of operations to create significant savings. For example, it may take only 2 minutes to cut/engrave a small part, but it will take an hour to set up to do it. Or, if you have 5 operations at 1.5 hours each, but only 30 minutes total machine time, then 7.5 hours is charged for just 30 minutes of processing.

Volume (number of parts to process) plays a critical role in amortizing the set-up time, design review time and other activities into the cost of the part. In the example above, the part in quantities of 10 could cost 7–10X the cost in quantities of 100. Typically, the law of diminishing returns presents itself at volumes of 100–300 because set-up times and fixturing can be amortized into the overall cost.

The objective is to design for lower cost. The cost is driven by time, so the design must minimize the time required to not just cut/engrave, but also the set-up time of the machine, design review/correction, fixturing and many other activities that are dependent on the complexity and size of the product.